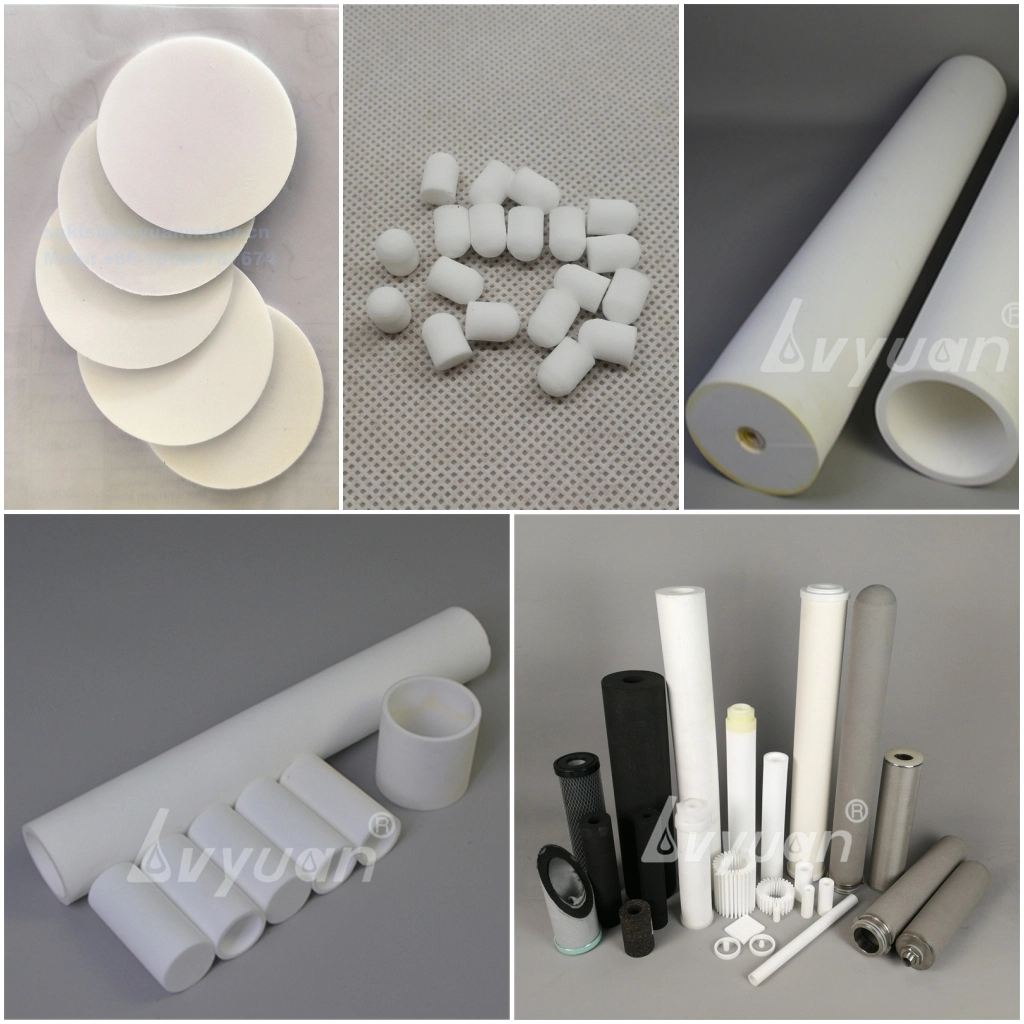

Sintered Porous plastic Filter cartridge Introduction:

Lvyuan produces wide ranges of sintered porous plastic filter products, including porous PE, HDPE, PTFE, PVDF, PA, Nylon 6, with shapes of tube, rod, candle, sheet, plate, disc, stick etc. With various filtration rate, shapes and features, sintered porous plastic filter cartridges are widely used in water treatment, chemical engineering, medical treatment, automobile, environmental protection and other industries, such as oil water separator and silencer, drunk driving tester, blind plug for medial treatment, syrup and grease filter device, anti-explosion slices for industrial battery, acid-proof slices for automobile battery, waste water treatment, water purification filter system and more. Lvyuan sintered porous platics filters can meet requirements of different customers. Custom molded Shapes are available.

Sintered porous plastic filter parameters:

material:Ultra High Molecular Weight Polyethylene (UHMWPE),HDPE, PVDF, PTFE, PA, Stainless steel, Titanium etc

Length: 80mm-2000mm or as customer's request

Outer diameter: Φ24mm-Φ1000mm, or as customer's request.

connection:flat,insert,screwed,222,226

micron rate: 0.2um, 0.45um, 1um, 3um, 5um, 10um, 25um, 30um, 50um, 75um, 100um etc

Sintered Filter PE, PA, PTFE, PVDF, PP specifications can be customized according to client's requirement.

Sintered porous plastic products application:

Medical & Pharmaceutical

1. Impurity removal, decarbonization and fine filtration.2. Acid Gas Dry deducting

3. Decarbonization Filtration

4. Self sealing filters in suction liner bag

5. Ventilator, Oxygen Machine, hospital filter, Humidification bottle.

Food & Beverage

1. Remaining yeast and diatomaceous earth filtration2. Clarification filtration in beverage

3. Water filtration in beverage, brewery

4. Sterile air filtration in beer and brewery

Oil & Gas

1. Organic Solvents recycling filtration2. Injection water filtration

3. Steam, Compresses air and catalyst filtration

4. Final product end filtration

Chemical

1. Catalyst recovery2. Medicine intermediate decarbonization and fine filtration

3. H2O2 process filtration

Water Treatment

1. Protection of reverse osmosis in desalting of sea water2. Sterile Ozone filtration and ozone aeration

3. Protection of ultra filter, RO, EDI systems

Industry

1. Filters in flue gas analysis and CEMS systems2. Air aeration

3. Muffler and Silencer

4. Compress air filtration

5. CMI Porous Metal Instrument filters

Sintered porous plastic filter products Factory tour:

Certifications: